Selection And User Of Materials

Materials for contacts : Ag , Ag-Cu , Ag-Cu-N , Ag-CdO , Ag-Ni , Ag-Pd , AgSnO2

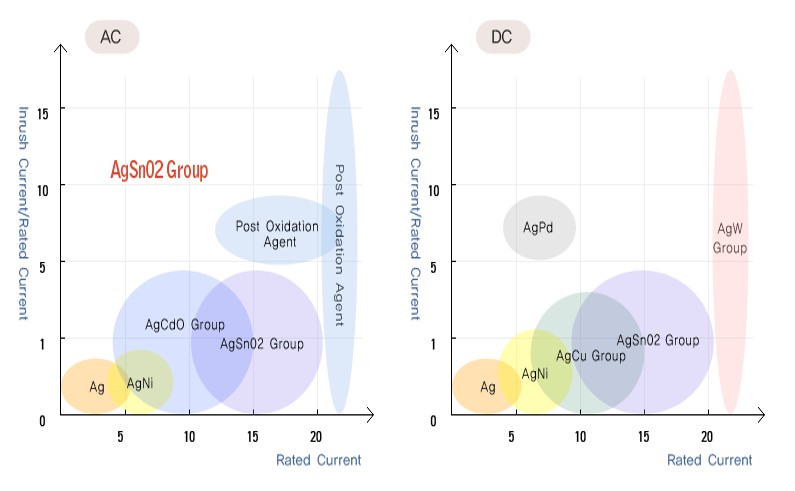

Electrical Contact Material & Application Load : Inrush Current / Rated

Selection And Use Of Materials for Electric Contacts

Materials For Contacts |

Physical&Chemical characteristics |

Main evaluation electric contacts |

Alloy composition |

Density |

M.P(℃) |

IACS% |

Applications |

Ag |

Thermal and electric conductivity is highest sulfurization is and oxides are decomposed by arcs. It is so ductile that it easy to machine it into various shapes. Weak points are thatmelting point hardness is low and its very easy to sulfurize Hard to beaffected by organic dases |

In widest use as electric contactsunder weak currents and middlecurrent conditions by causing it to have sliding action. |

Pure Ag |

10.5 |

961 |

106 |

Snap switches for low currents, thermostats , low current switches, electromagnetic contactors breakers in air breakers in oil, light load relays, switchesfor home electric appliances and rotaryswitches. |

Ag-Cu |

Hardness and wear resistance improves by adding Cu but easy to be oxidized. Alloys with content of less than 25% Cu are relatively ductile. Like Ag, can be machined into various shapes. |

Melting and adhering ability are improved and contact resistances comparatively large. But it is necessary to make contact pressure relatively great and sliding action go. Comparatively cheap. |

90% Ag-Cu |

10.3 |

778 |

85 |

Switches for home electric applianceselectric device for vehicles(circuit switches winkers from lighting switches,horns and voltage regulators),relays for light load breakers in air for controlnd change gears),, automatic vendingmachines slip rings, and rotary switches. |

Ag-CdO |

Harder than Ag because it is alloy with CdO diffused in Ag. Conductivitys higher than Ag-Cd alloy.CdO is stable against oxidation and atmospheric pressure is high so it easy to dissociate. Arc removal takes place. |

Alloys containing up to 15% caoare commonly used. Resistant tomelting and adhering better thanAg under middle current and high current conditions. Wear characteristics due to improves. |

85~88% CdO |

10~10.1 |

961 |

70~75 |

Breakers in air, arc resistant armaturesregulators of overload, relays for heavy load, electromagnetic contactors, relays for middle load, snap switches, thermostats, electric devices for vehicle, and switch for middle current. |

Ag-Cu-N |

Mechanical quality is better than Ag-Cu. |

Less wear and shift. |

75%Ag 24.5%Cu 0.5%Ni |

10.1 |

810 |

68 |

Tap selection, switches for low current,television regulators, relays for light load, and relays for middle load. |

Ag-Ni |

This alloy is made by powder metallurgy method. Hardness and resistance are improved, having comparatinely good ductility and conductivity being good. |

Comparatively small in wear amount when making and breaking frequency is often or contact pressure is high under middle and large current condition. |

90% Ag-Ni |

10.3 |

961 |

65 |

Breakers in air, breakers in oil, electromagnetic contactors, electromotive starters, electric devices for vehicles (maiin current breakers and winkers), and thermostats |

Ag-Pd |

Resistance to sulfurization improvesbetter than Ag and less affectted bypoisonous gases than Pd. |

Wear amount becomes small and contact resistance becomes stable under the condition where contact pressure is great and arcwith much breaking and making frequency arises. Suitable for sliding contacts under low current condition. |

70%Ag-Pd |

10.9 |

1225 |

11.5 |

Thermostats, relays for light load, relays for aircrafts, electric devices for vehicles, switches for generators(winkers, Voltage regulators), relays for telephones, dials, micromotors, relays for electronic switchboards,etc. |

Ag-SnO2 |

Thermally most stable among the metallic oxides of other Ag alloy. High resistance against erosion. Stand to current density of more than 1.5times of AgCdO's. Substitute some of WC contacts of today. |

Any type of switchgear requiringbreaking capacity in AC or DC at10 to 1000A and 24 to 600V. This material is recommended for itslow welding tendency and for the resistance stability when subject ed to intense make and break cycles. |

88%Ag-SnO2 |

10.1 |

961 |

70 |

Switchgear type (relays, contactors, en gine starters, breakers) Industrial automatisms Transport cars, railways Lifts, forklift trucks Regulating devices, thermostats |

Applcable Load

Materials : Ag , Cu , Ag-Cu , Ag-Ni , Ag-Pd, Ag-CdO,Ag-SnO2 Etc